LAB Line Overview

The Kurt J. Lesker Company® LAB Line UHV Sputter platform is purpose built for magnetron sputtering deposition applications. A chamber design tailored to fit UHV sputter process needs, an industry best software control system with advanced programming, load lock capability, and numerous features for optimized thin film performance are a few of the advantages offered in this innovative design.

The LAB Line series is compatible with the following techniques:

- TORUS® Magnetron Sputtering (up to 12 sources)

- Custom configurations are available upon request

KJLC's innovative eKLipse™ software allows user-friendly recipe creation along with a graphical user interface that is intuitive for new PVD users whilst advanced for seasoned professionals. For more information on this intuitive, unique, and reliable software package, please see the Software Tab.

Applications:

- R&D Sputter Deposition

- Microelectronics (Metals, Metal Oxides, Dielectrics)

- Data Storage (Magnetic thin films)

- Magnetic Tunnel Junctions

- Superconducting Materials

- Josephson Junctions

- Optical Films and Photonics

LAB Line Features

Optimized UHV Process Chamber- Cylindrical 304L Stainless Steel chamber optimized for UHV Magnetron Sputtering processes

- Top plate hoist

- Chamber design is optimized for confocal sputtering source arrangement, compatible with UHV pressure regime, and allows convenient access through top-plate for target change and maintenance

- Option 1 - Nominally 14" (356mm) O.D. x 20" (508mm) High (Sputter 5)

- Option 2 - Nominally 20" (508mm ) O.D. x 26.6" (676mm) High (Sputter 12)

|

| Vacuum Pumping & Gauging- Industry leading Pfeiffer 1250 L/s turbomolecular pump with an Edwards XDS35i dry scroll roughing pump. Base pressure for a properly conditioned chamber is 9 x 10-9 Torr

- Nude ion gauge and convection gauge read from atmosphere to 10-10 Torr

|

SafetyFully enclosed system electronics rack. - Allows all electrical components to be safely housed

- EMO Protection is standard on all KJLC systems

- Isolation transformer and safety interlocks are standard on all KJLC systems

|  |

| QualityUtilizing industry leading components allows KJLC to produce the highest quality PVD tools on the market. Components and key manufacturing points are: - One year warranty standard

- Pfeiffer Turbomolecular pumps

- CTI-Cryogenics® Cryopump Systems

- KJLC Torus sputter sources, and power supplies

- Orbital welding on all process gas lines / manifolds

- Systems within the European Economic Area (EEA) are CE marked and comply with the following EU directives:

- Low Voltage Directive (LVD) 2014/35/EU

- Electromagnetic Compatibility (EMC) Directive 2014/30/EU

- Systems outside of the EEA can be CE marked for an additional cost

|

LAB Line Performance

PumpingThe LAB Line offers two types of high vacuum pumping on its process chamber, a 1250L/s Pfeiffer turbomolecular pump or Brooks CTI-8F 1500 L/s, or cryo pump. The Pfeiffer turbomolecular pumps being a good choice for overall cost effective high quality pumping particularly for reactive sputtering applications. The Brook CTI cryo pumps find use in applications that require the lowest vacuum possible. |

DepositionThe LAB Line is Kurt J. Lesker's UHV magnetron sputtering platform. Only KJLC offers Mag-Keeper sputter sources with zero o-rings in the cathode body and a magnetically coupled target to allow for easy target changes. Our "patent pending" cooling well design enables operation at power densities up to 200 watts/.in2. This cathode is designed to sputter up to a 0.375" thick targets. Without a hold down clamp or dark space shield this cathode is capable of running as low as ≤ 1mTorr (material dependent). The unique dome shutter design eliminates the need for additional cross contamination shielding required with standard flip or swing shutters. Click to learn more about sputtering rates and uniformity. |

The LAB Line has been designed for optimal uniformities and allows. The chart to the left shows average expected uniformity by deposition type and substrate wafer diameter. Thickness measurements were made using a Profilometer or spectral reflectometer. The actual uniformity achievable will be a function of the final configuration of the system and process parameters. | Typical Deposition Uniformities| Sources | Wafer size | Uniformity | | TORUS® Sputtering Sources | 150mm Wafer | <=+/-5% |

|

| TORUS® sources are operated at typical sputtering pressures (≤20 mTorr) and utilize Si wafers for deposition. SiO2 Target run with RF Power, film thickness >=500Å. Al Target run with DC Power, film thickness >=1500Å. Ni Target run with High Strength TORUS® & DC Power, film thickness >=1500Å. - All Films are measured on a properly calibrated Profilometer, Reflectometer or Ellipsometer (if applicable)

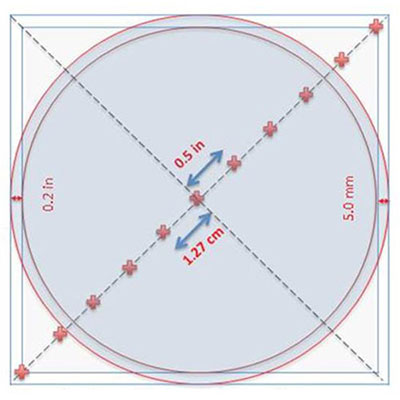

- Measurement points are taken starting at the center of the substrate and then radially outward every 0.5 inches (12.7mm), nominally (reference figure to the left)

- Uniformity calculation formula is: ((Max - Min) / (2 x Avg)) x 100% with a 0.2 inch (5mm) edge exclusion

|